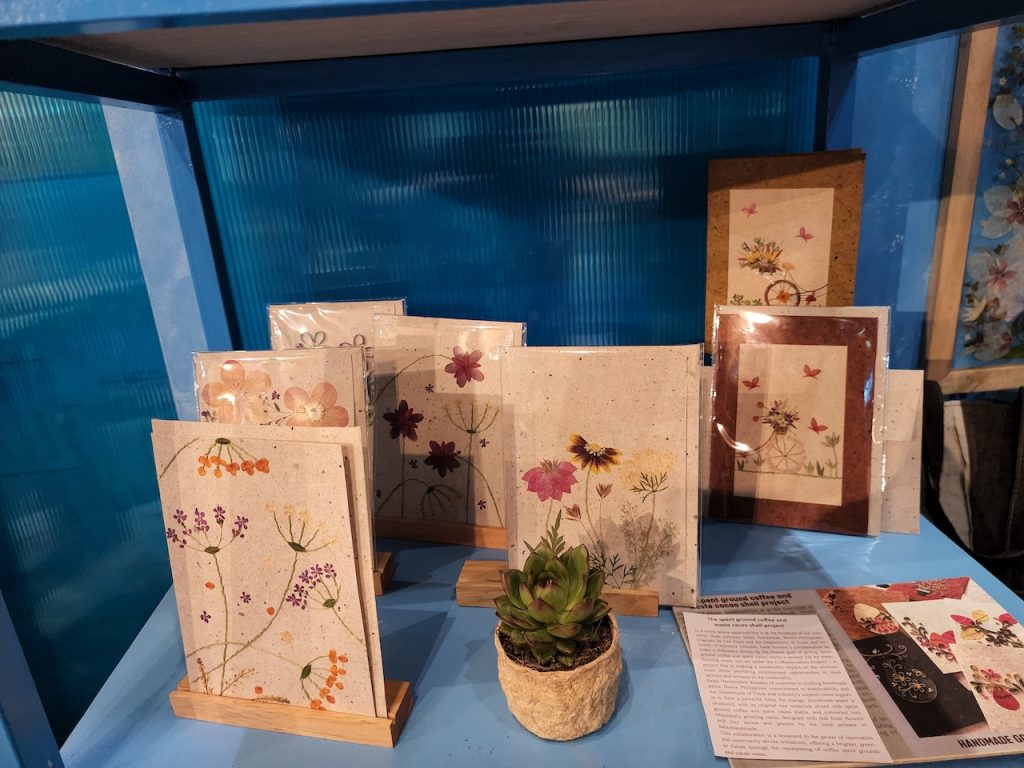

While technology may have taken away much of the excitement of receiving greeting cards neatly-sealed in envelopes, for the “eyes of the beholder,” the joy of receiving and opening them remain to be very meaningful and heart-felt.

Moreso if these are hand-crafted. They exude such a classic impression that recipients will most likely be impressed at how they have been neatly and creatively put together.

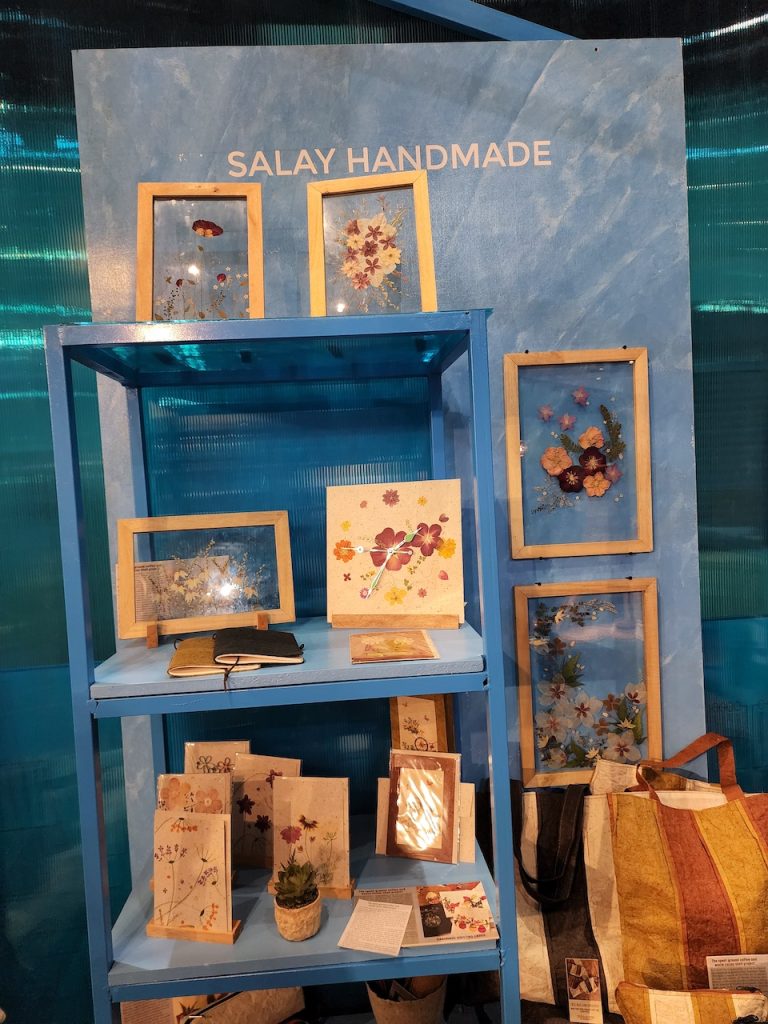

This is the niche Salay Handmade has been producing. Its top quality hand-made greeting cards never fall out of fashion, even in a “high-tech” and modern world.

Salay Handmade thus continues to create these precious products and exports 90 percent of these kinds to this day.

Showcased at the recent Manila FAME at the World Trade Center in Pasay City, these hand-crafted greeting cards are being exported to the United Kingdom, Europe and the United States.

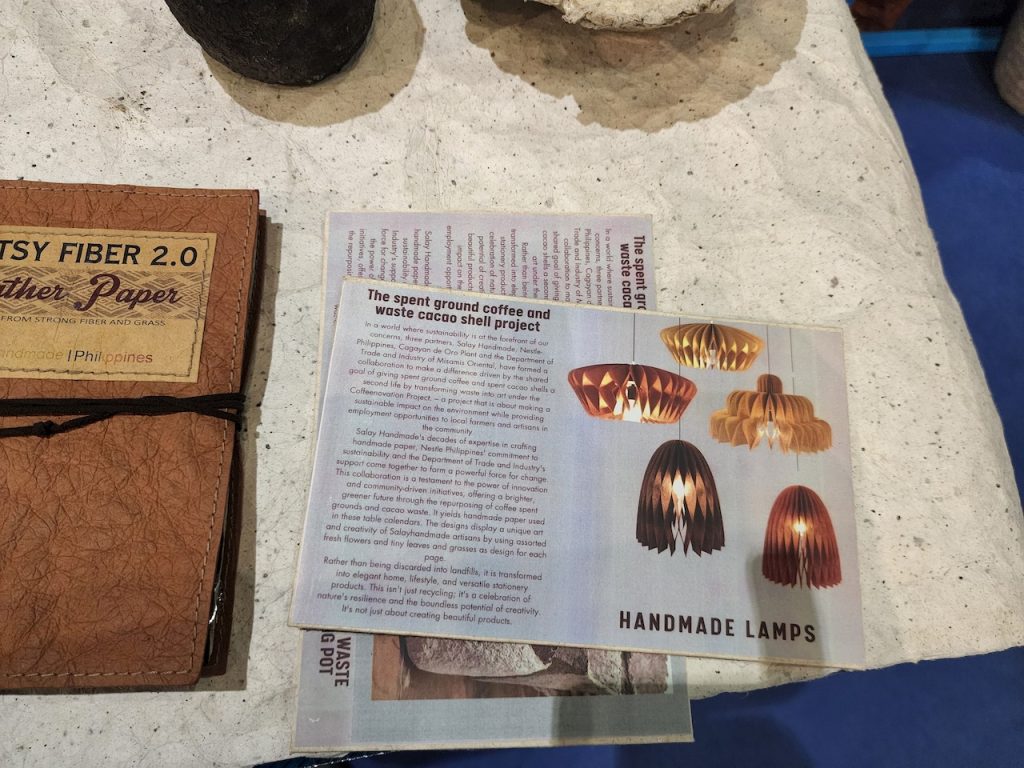

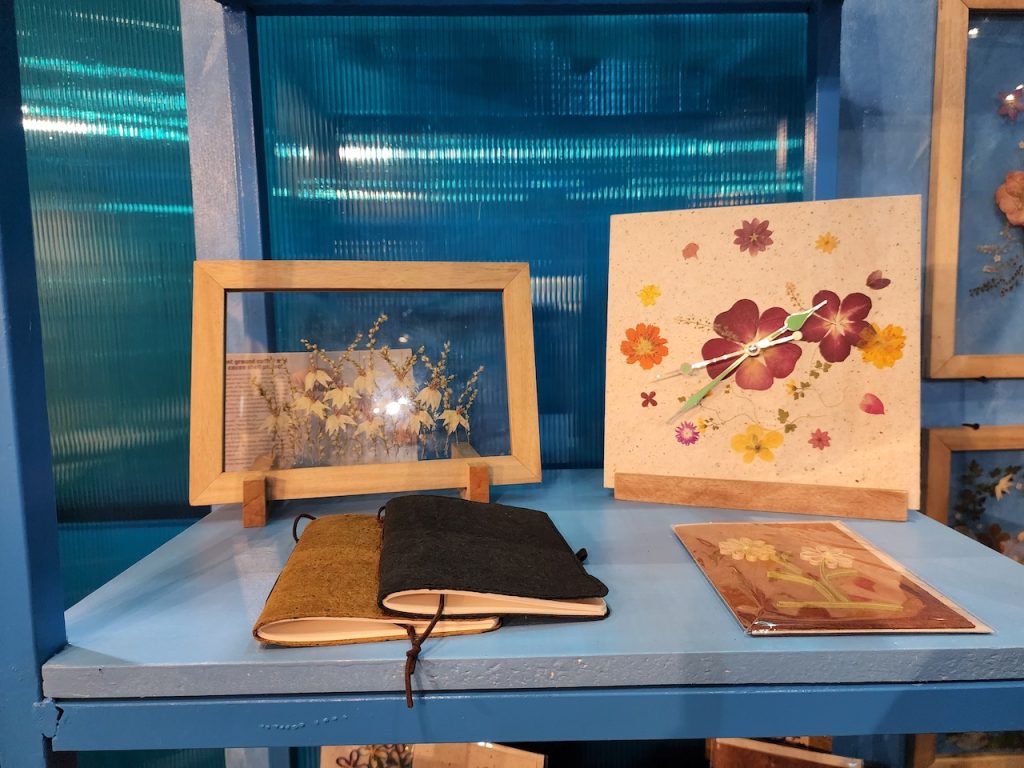

An array of other products were also especially displayed in the event. Their designs, quality and sturdy built were quite awesome, considering that they are made of paper.

Referring specifically to the greeting cards, Salay Handmade President Neil Francis Rafisura, has this to say:

“Some are surprised (about these greeting cards. They thought the designs come from a professional designer. But actually, they come from normal (ordinary) people; simple people.”

He notes these greeting cards have become the company’s bread and butter, following the easing out of other products, which used to be blockbusters in the international market.

Among these extinct hand-made products were writing stationaries, photo albums, journals and photo frames.

“We used to have lot of men work on these photo frames and boxes. So now, we retain the women, the young mothers, housewives of fishermen and farmers, because it is cultural,” Mr. Rafisura adds.

For 36 years, the company has evolved from a small, creative industry which helped ordinary people survive amid heavy fighting in the rural areas, to an exporting entity that has established partners and Western clientele.

“We started in 1987, in the middle of the insurgency problem between the NPAs and the armies. There were a lot of fighting in the mountains because of the rebellions. So people from the mountains will go to the barangay or poblacion. They didn’t have jobs, food and medicines.

It was the time that my parents decided to make a livelihood project for them. So, the strategy was to make hand-made paper using cogon grass.

But the idea of having hand-made paper came from the Design Center of the Philippines, who happened to have demonstrated how to produce this,” Mr. Rafisura recalls.

Thereafter, his parents requested training from the Department of Trade and Industry. The training started with 50 people, with the end in view of producing something like common bond paper, but the products didn’t turn out as they were expected. Thus, only 10 people remained in the workforce.

“But my parents did not stop and just continued doing some experiments, until in the 1990s, we were discovered by some Japanese, who invited us to go to Japan and gave us more trainings on hand-made paper-making to refine our art,” he tells EmbassyTOPPs.

Thereafter, Salay Handmade started exporting, little by little, first to Japan and then in the US.

Mr. Rafisura then went to Europe to do some marketing, and then buyers went to Salay (Misamis Oriental), bought their products and partnered with them. And since then, his company has found support from their (business partners) as well as government and non-government agencies.

Calling themselves “DTI babies” in the early part of their export journey, the company president underscores how DTI helped Salay Handmade take off.

“But sometimes, during lean times or hard times, we had to turn to them to ask for help, especially when fairs and events such as Manila FAME become too expensive (to exhibit products).

The government has always been so good to us, ever since. They never let us down. Every time we ask for assistance, marketing, market access, product development…DTI is there, and so are DOST (Department of Science and Technology) and other government agencies,” Mr. Rafisura stresses.

Without these entities, he notes Salay Handmade cannot survive on its own, considering that its officials are not businessmen, nor are they technical people or engineers.

But while the company has been doing good all these years, the handmade-paper industry faces a lot of challenges.

“The industry in the Philippines is very small. It is a dying industry. We used to have a strong one during President Ramos, but now, we have been overtaken by Thailand, Bangladesh and Nepal. But in terms of quality, reliability and word of honor, the Filipino is still great in terms of designs,” Mr. Rafisura explains.

He laments that the two top factors that hinder Salay Handmade’s products from competing in the industry are the country’s labor cost, which he says, is considered the highest in Asia; and the high cost of electricity.

Being a manufacturing company, Mr. Rafisura says, these factors hurt Salay Handmade a lot.

The only redeeming factor for his products, he notes, are the designs that stand out against competitors.

Should he get a chance to talk to policy-makers and legislators to help the industry compete and flourish in an highly-competitive industry, Mr. Rafisura would like to have an exemption from the minimum wage law, which regularly continues to rise.

“It doesn’t mean that we don’t respect the disadvantaged producers. We respect them, we want to help them. We want to give them the living wage. We’re not exploiting them. But that’s far below the minimum wage and they need to be exempted from other benefits or perhaps, taxes,” he notes.

“Give us some space to breathe and survive. It’s a very competitive industry,” Mr. Rafisura adds.